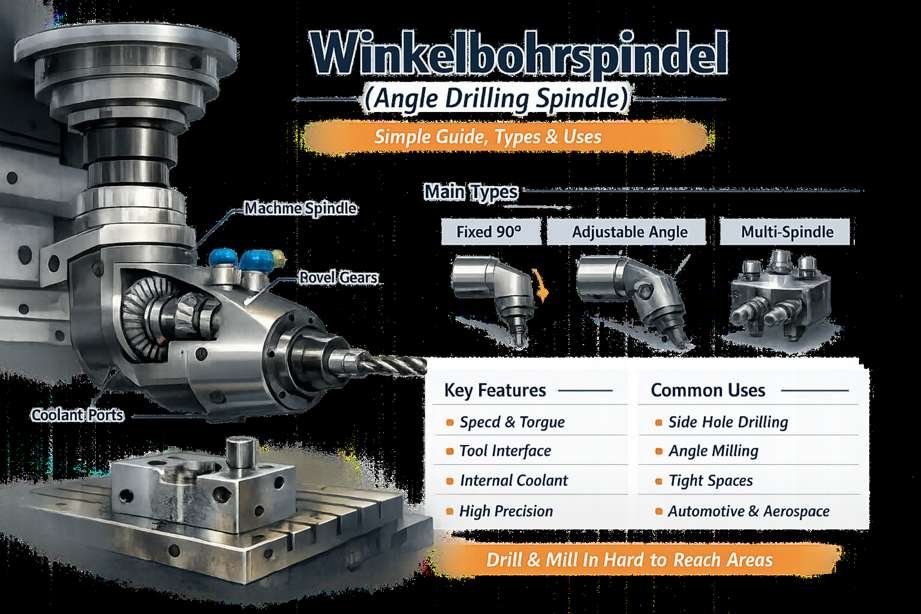

Winkelbohrspindel: A Simple Guide to Angle Drilling Spindles

In modern manufacturing, many machine parts have complex shapes. Often, it is not possible to drill or mill a hole in a straight line because the tool cannot reach the place where the hole is needed. This problem is common in tight spaces and on parts with side holes. A Winkelbohrspindel, also called an angle drilling spindle or angle head, helps solve this problem.

A Winkelbohrspindel changes the direction of rotation of the machine spindle, usually by 90 degrees. This makes it possible to drill, mill, or tap holes on the side of a part without moving or turning the workpiece. These spindles are widely used on CNC machines, production machines, and special-purpose machines in many industries.

This article explains what a Winkelbohrspindel is, how it works, the main types, technical features, applications, advantages, limits, and how to choose the right one.

What Is a Winkelbohrspindel?

A Winkelbohrspindel is a machine tool attachment or unit that sends rotation from the machine spindle to a cutting tool at an angle. The most common angle is 90 degrees, but some models can work at different angles.

Main Points

-

Changes tool direction (usually 90°)

-

Used for drilling, milling, tapping

-

Works on CNC machines and production machines

-

Helps machine hard-to-reach areas

-

Available as fixed-angle or adjustable-angle tools

How Does a Winkelbohrspindel Work?

A Winkelbohrspindel uses gears to change the direction of rotation from the machine spindle to the cutting tool.

Main Parts

-

Input shaft – connects to the machine spindle

-

Gear system – changes direction of rotation

-

Output spindle – holds the cutting tool

-

Bearings – support the moving parts

-

Housing – the body of the spindle

How Power Is Transmitted

-

Rotation is sent through angle gears (bevel gears)

-

The speed can be:

-

Same at input and output

-

Higher at output (high-speed models)

-

Lower at output (high-torque models)

-

-

The machine usually moves the tool forward and backward

-

The Winkelbohrspindel itself normally does not move forward

Types of Winkelbohrspindeln

There are different types for different jobs.

Common Types

-

Fixed 90-degree angle spindle

-

Adjustable-angle spindle

-

Multi-spindle angle head (more than one tool)

-

High-speed spindle

-

High-torque spindle

-

Removable spindle head

-

Built-in machine spindle unit

Type Comparison

| Type | Main Feature | Typical Use |

|---|---|---|

| Fixed 90° | Always 90-degree angle | Side drilling |

| Adjustable Angle | Angle can be changed | Complex parts |

| Multi-Spindle | Several tools at once | Mass production |

| High-Speed | High rotation speed | Small holes |

| High-Torque | Strong cutting force | Large holes |

| Removable Head | Can be removed | Flexible use |

Technical Data (Simple Overview)

When choosing a Winkelbohrspindel, these points are important.

Important Technical Values

-

Maximum speed (RPM)

-

Torque (cutting power)

-

Gear ratio

-

Accuracy (runout)

-

Bearing quality

-

Size and weight

-

Tool holder type

-

Coolant support

Simple Technical Table

| Parameter | What It Means | Why It Is Important |

|---|---|---|

| Speed (RPM) | How fast it can turn | For small or large tools |

| Torque | How strong it is | For hard materials |

| Runout | How straight it runs | Hole quality |

| Bearings | Support for rotation | Smooth running |

| Size | Physical size | Fit inside machine |

| Weight | How heavy it is | Load on machine |

Tool and Machine Connection

The Winkelbohrspindel must fit both the machine and the cutting tools.

Machine-Side Connection (Examples)

-

HSK

-

ISO

-

BT

-

VDI

-

Capto

Tool-Side Connection

-

ER collets

-

Weldon shanks

-

Quick-change systems

Fit Check List

-

✔ Fits machine spindle

-

✔ Has anti-rotation support

-

✔ Enough space around tool

-

✔ Works with tool holder system

-

✔ Safe mounting

Coolant and Lubrication

Cooling is important to protect tools and the spindle.

Coolant Types

-

External coolant spray

-

Internal coolant through the spindle

-

High-pressure coolant

-

Air blast

Why Internal Coolant Is Helpful

-

Chips are removed better

-

Tools stay cooler

-

Tools last longer

-

Better hole quality

Applications of Winkelbohrspindeln

Winkelbohrspindeln are used in many machining tasks.

Typical Uses

-

Drilling side holes

-

Milling on side faces

-

Tapping holes at an angle

-

Working in narrow spaces

-

Machining without turning the part

Industry Examples

| Industry | Example Use |

|---|---|

| Automotive | Engine and gearbox parts |

| Aerospace | Aircraft structure parts |

| Machinery | Housings and frames |

| Plastics/Wood | Compact machining jobs |

| Production Lines | Multi-hole drilling |

Advantages

Using a Winkelbohrspindel has many benefits:

-

Can reach places straight tools cannot

-

Less need to move or turn the part

-

Faster production

-

Fewer machine setups

-

More flexible machining

-

Can be used on existing machines

Limitations

There are also some limits:

-

Less power than straight spindles

-

Gears can wear over time

-

Needs careful maintenance

-

Can be more expensive than simple tools

-

More risk of collision if space is tight

How to Choose the Right Winkelbohrspindel

Before buying, think about these points:

Selection Tips

-

What work will you do (drilling, milling, tapping)?

-

Do you need high speed or high torque?

-

Does it fit your machine type?

-

Is there enough space in the machine?

-

Do you need internal coolant?

-

Is it for single parts or mass production?

Simple Decision Table

| Your Need | Best Choice |

|---|---|

| Small holes | High-speed spindle |

| Large holes | High-torque spindle |

| Many holes at once | Multi-spindle head |

| Different angles | Adjustable-angle spindle |

| Tight space | Compact 90° spindle |

Installation, Maintenance, and Safety

Installation Steps

-

Mount the spindle firmly

-

Align it correctly

-

Install anti-rotation support

-

Test run without cutting

-

Check CNC program paths

Maintenance Tasks

-

Lubricate gears and bearings

-

Check for noise or vibration

-

Clean coolant channels

-

Inspect for wear

Safety Tips

-

Do not exceed maximum speed

-

Do not overload the tool

-

Check for collisions in simulation

-

Train operators

Winkelbohrspindel vs Other Solutions

| Solution | Pros | Cons |

|---|---|---|

| Winkelbohrspindel | Simple, compact, flexible | Less power |

| 5-Axis Machine | Very flexible | Very expensive |

| Reposition Part | No extra tools | Slower process |

| Special Head | Strong and stable | Less flexible |

Conclusion

A Winkelbohrspindel is a very useful tool for modern machining. It makes it possible to drill and mill in places where normal tools cannot reach. This helps save time, reduce machine setups, and improve production speed. While it needs proper selection and regular maintenance, the benefits in flexibility and productivity make it a good choice for many manufacturing tasks.

If you want to improve your machining process and work with complex parts, a Winkelbohrspindel can be a smart and practical solution.