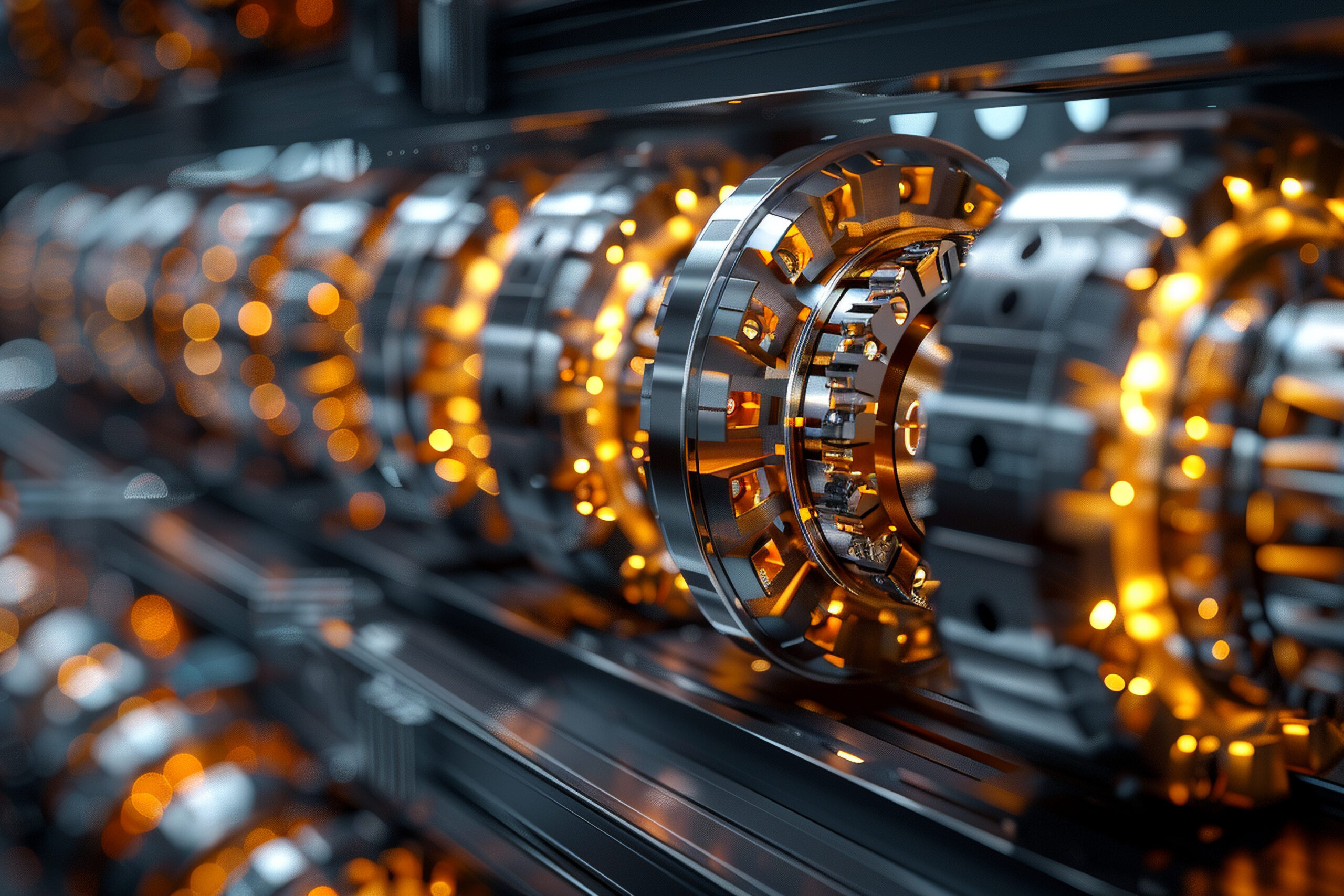

Quality Machined Parts for Industrial Applications

Complex industrial machinery relies on the seamless interaction of countless components. From the smallest screw to the largest gear, every part plays a vital role in ensuring safe, efficient, and reliable operation. When even one of these components fails, the consequences can range from minor production delays to catastrophic equipment failure, leading to significant financial losses and safety hazards. This is why sourcing high-quality machined parts is not just a procurement decision; it’s a critical investment in your operation’s success and longevity.

Understanding what defines a quality machined part is the first step toward building a more resilient and productive industrial environment. This post will explore the key characteristics of superior components, the advanced manufacturing processes used to create them, and the long-term benefits of prioritizing quality in your supply chain. By the end, you’ll have a clear framework for evaluating and selecting the right parts for your specific industrial applications.

What Defines a Quality Machined Part?

Not all machined parts are created equal. Superior components are defined by several key attributes that collectively ensure they perform as expected under demanding industrial conditions. When evaluating parts for your machinery, look for the following indicators of quality.

Material Integrity and Selection

The foundation of any durable part is the raw material from which it is made. Quality begins with selecting the right grade of metal, alloy, or polymer for the specific application. The material must possess the required properties, such as tensile strength, corrosion resistance, heat tolerance, and hardness. Reputable manufacturers use materials that meet strict industry standards (like those from ASTM or ISO) and can provide documentation to verify the material’s origin and composition. This traceability is crucial for ensuring that the part will withstand the environmental and mechanical stresses it will encounter.

Precision and Dimensional Accuracy

Industrial machinery often operates with incredibly tight tolerances, where even a slight deviation can cause a system to fail. Quality machined parts are manufactured with exceptional precision, adhering strictly to the design specifications. Dimensional accuracy ensures that components fit together perfectly, move smoothly, and distribute loads correctly. Advanced measuring tools, such as coordinate measuring machines (CMMs), are used during and after production to verify that every dimension—from diameter and length to flatness and concentricity—is within the specified tolerance.

Superior Surface Finish

The surface finish of a part is more than just a cosmetic feature. A smooth, properly finished surface reduces friction, minimizes wear and tear, and improves resistance to corrosion and fatigue. Different applications require different surface textures. For example, a bearing surface needs to be extremely smooth to allow for free movement, while a sealing surface might require a specific roughness to ensure a tight seal. A quality manufacturer will have the capability to achieve the precise surface finish required for optimal performance and longevity.

Advanced Manufacturing for Superior Parts

Achieving the high standards required for industrial parts depends on sophisticated manufacturing techniques. Modern machine shops leverage advanced technology to produce components that are both complex and precise. Processes like CNC milling and turning have revolutionized the industry, allowing for the creation of parts with a level of accuracy and repeatability that was previously impossible.

Computer Numerical Control (CNC) machining uses computer-guided tools to cut and shape raw materials. This automation minimizes the potential for human error and allows for the production of intricate geometries with consistent quality. By using these advanced methods, manufacturers can produce parts that meet the most demanding specifications, ensuring reliability in critical applications.

The Benefits of Investing in Quality

While high-quality machined parts may come with a higher initial cost, the long-term benefits far outweigh the upfront investment.

- Increased Reliability and Uptime: Well-made parts are less likely to fail prematurely. This reduces unexpected equipment breakdowns, minimizes production downtime, and helps maintain consistent operational output.

- Enhanced Safety: In many industrial settings, component failure can pose a serious risk to personnel. Using certified, high-integrity parts is a fundamental aspect of maintaining a safe working environment.

- Lower Maintenance Costs: Durable components last longer and require less frequent replacement. This translates to lower lifetime maintenance costs and reduced labor expenses associated with repairs.

- Improved Performance: Precision-engineered parts ensure that machinery operates at its optimal efficiency. This can lead to better product quality, faster production speeds, and lower energy consumption.

Securing Your Operational Success

In the industrial sector, the strength of your operation is only as strong as its weakest link. Investing in high-quality, precisely engineered machined parts is essential for ensuring the reliability, safety, and efficiency of your equipment. By prioritizing material integrity, dimensional accuracy, and superior surface finish, you can build a more robust and profitable operation.

Partnering with a manufacturer that demonstrates a commitment to quality and utilizes advanced production technologies will provide you with the dependable components needed to thrive. Make the smart investment in quality parts today to secure your operational success for years to come.